To meet the demands of a rapidly growing market for green hydrogen, water electrolysis capacity using electrical energy from renewable sources to split water into oxygen and hydrogen has to be ramped up accordingly. Commercially established water electrolyzers based on a proton-exchange membrane (PEM) show advantages as e.g. a sufficient lifetime and capability of high current densities. However, the demand of catalysts made of rare and costly platinum group metals (PGMs) as iridium are a drawback for upscaling. Besides the need for PGMs, the use of perfluorosulfonic acids (PFSAs) to exchange protons in PEM based systems are a huge environmental concern.

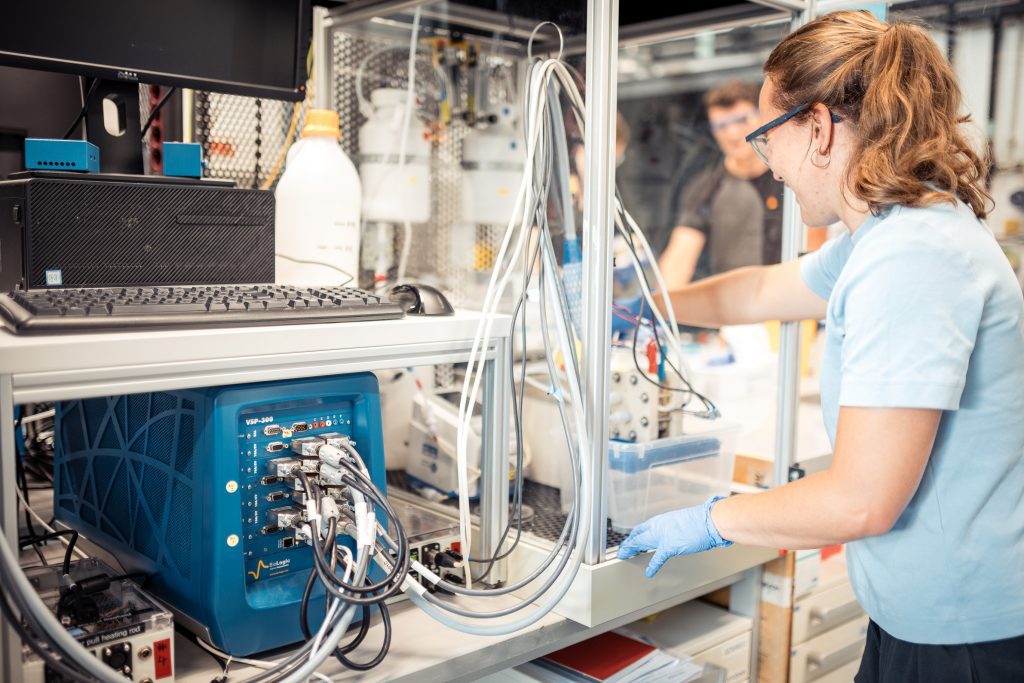

The interdisciplinary PEM water electrolysis team focuses on the development of novel membrane-electrode assemblies (MEAs) to address the reduction of the noble metal loading e.g. by smart catalyst layer designs. The PEM electrolysis team is also working closely together with the EES Polymers group to study and develop fluorine-free MEAs. The whole MEA development cycle from catalyst synthesis to MEA in- and ex-situ characterization can be performed in-house bringing together the knowledge and know-how of many different disciplines and methods.